Warehouse Temperature Monitoring Systems

While wired temperature monitoring systems are a common tool to monitor temperature in cold storage warehouses, newer remote temperature monitoring systems are a much better way to measure, collect, and wirelessly transmit data for warehouse temperature and other storage conditions.

How E-Control’s Temperature and Humidity Monitoring Systems For Warehouses Work

E-Control Systems is a comprehensive solution designed for warehouses and similar facilities to monitor and manage critical environmental parameters in real-time. It uses wireless sensors to collect data on temperature, humidity, air quality, and energy consumption, which is then analyzed and processed in a centralized system. The system provides customizable alerts for any parameter outside the acceptable range, ensuring immediate action can be taken to prevent issues.

Data logging and reporting features allow for historical analysis and identification of improvement areas, while remote access enables monitoring and intervention from anywhere. Energy management and compliance support are also included. Overall, E-Control Systems helps warehouses maintain optimal conditions, improve efficiency, and meet regulatory standards.

E-Control Systems Features for Warehouses

What makes E-Control Systems stand out? Our sensors and intelligates can monitor any aspect of your Warehouses business 24/7.

What Sets Our Warehouse Temperature Monitoring Systems Apart from Other Options in the Market?

E-Control Systems stands out from other warehouse monitoring options for several key reasons. Our comprehensive approach covers critical environmental parameters like temperature, humidity, air quality, and energy consumption, ensuring optimal conditions for stored goods. With real-time monitoring capabilities and customizable alerts, warehouses receive instant updates on deviations from desired parameters, enabling immediate action to prevent issues and minimize risks.

Scalability and flexibility make our solution suitable for warehouses of all sizes and configurations. We can handle large columns of data from multiple sensors, accommodating the needs of both small and large operations. The Remote access feature allows authorized personnel to monitor and manage the warehouse environment from anywhere with an internet connection, facilitating quick decision-making and intervention.

Our Warehouse Customers Include:

Warehouse Temperature Control Devices and Censors

Continuously monitoring your cold storage warehouse temperature is essential to ensuring the safety of temperature-sensitive goods like fresh food, produce, or medicines and vaccines. Small changes in temperatures can cause huge problems, which is why remote temperature monitoring systems are crucial to maintain both the safety of stored goods. They are also invaluable to prove that a warehouse follows strict quality control processes if needed.

What is a Remote Temperature Monitoring System for Warehouses?

A remote temperature monitoring system is a set of temperature sensors that are set up to monitor temperatures and other conditions, such as pressure and humidity, to fit your specific needs. Once these measurements are collected from the sensors they are transmitted to a readable format on a dashboard in which alerts can be sent when conditions move outside preset ranges. The system can be set up to flag any spikes in ambient temperature and send customized alerts to a central warehouse monitoring system or to individual stakeholders through an alert on any device. This data is also sent and stored in the cloud where the data can be shared or acted upon.

Wireless Warehouse Temperature Sensors VS. Wired Sensors?

There are 3 important factors to consider when choosing what system is right for your warehouse:

- Cost – Make sure you keep installation in mind when thinking of cost.

- Reliability

- Scalability / Flexibility

Wired and wireless sensors each have their own pros and cons, for most cold chain warehouses wireless temperature monitoring systems are the way to go.

Lower Installation and Operating Costs

There’s no need to install any wiring make any major changes to your warehouse. This ease of installation makes it easier to install wireless remote temperature monitoring systems in shared warehouse space or older warehouses that my not be conducive to changes. Improvements in connectivity and better manufacturing processes have also reduced the costs of remote wireless temperature monitoring systems.

Easy to Install, Modify, and Scale

All you need to set up a wireless warehouse temperature monitoring system are the sensors and access to the internet. The compact nature of the sensors and no need for wiring makes them easy to install a wireless temperature monitoring system in areas that may not be accessible to a wired temperature monitoring system.

Increased Deployment Time

New technology such as Bluetooth mean that battery powered wireless temperature sensors can run for months, or perhaps even years before needing a change in batteries. The cost of powering a wired temperature monitoring system, especially in a large warehouse space, would be much greater than the cost of running a wireless remote temperature monitoring system.

Much More Reliable

Unlike wired temperature monitoring system, a wireless remote temperature monitoring system doesn’t have to be in constant contact with a central system. Problems with wiring or power outages will cause issues with a wired temperature monitoring system, but a wireless remote temperature monitoring system can store sensor readings until connectivity is restored. This means no gaps in monitoring and the safety of your data.

What is a temperature and humidity monitoring system for warehouses?

Warehouse temperature monitoring is a technology solution designed to continuously measure and record the temperature and humidity levels within the storage facility. This system typically consists of sensors placed throughout the warehouse that collect data on environmental conditions. The data is then transmitted to a central monitoring system, where it can be analyzed in real time to ensure that the temperature and humidity remain within specified ranges. This is important for maintaining the quality and integrity of temperature-sensitive and humidity-sensitive goods, such as food products, pharmaceuticals, electronics, and other perishable items. The warehouse temperature monitoring system can also alert warehouse managers to any deviations from set parameters, allowing for immediate corrective actions to prevent spoilage or damage to stored goods.

What are warehouse temperature standards?

The ideal warehouse temperature depends on the types of products stored and their specific storage requirements. Generally, for a broad range of goods, maintaining a temperature between 50°F to 75°F is considered acceptable. However, this can vary significantly:

- Perishable Food Items: Require refrigerated or frozen temperatures specific to the type of food being stored. Refrigerated goods typically need to be kept between 34°F and 38°F, while frozen goods are stored at 0°F or lower.

- Pharmaceuticals: Many medications and vaccines require strict temperature control, often within a narrow range that can be as specific as 2°C to 8°C for refrigerated products.

- Electronics and Machinery: Preferably stored in conditions that avoid extremes of temperature and humidity to prevent condensation and overheating, usually at room temperature with controlled humidity.

- Chemicals: Certain chemicals need specific temperatures to maintain their stability and prevent reactions.

Adjusting warehouse temperatures according to the specific requirements of the goods stored ensures product integrity and complies with regulatory standards. Warehouse operators should understand and implement the correct temperature settings for specific storage needs.

What is a warehouse temperature data logger?

A warehouse temperature data logger is a digital device designed to record and store temperature readings over a period of time within a storage facility. These devices are equipped with sensors that measure the ambient temperature at set intervals and log this information into an internal memory. Temperature data loggers vary in complexity and functionality, ranging from basic models that simply record minimum and maximum temperatures to more advanced versions that offer real-time monitoring, wireless connectivity, and the ability to measure additional environmental parameters like humidity.

The collected data can then be downloaded or wirelessly transmitted to a computer or cloud-based system for analysis. This allows warehouse managers to monitor temperature fluctuations, ensure that goods are stored under optimal conditions, and comply with regulatory requirements. Temperature data loggers are essential tools for maintaining the quality and safety of temperature-sensitive products like food, pharmaceuticals, chemicals, and electronics, providing a verifiable record that storage conditions have been consistently maintained within required parameters.

How cold can a warehouse be legally?

The legal minimum temperature for a warehouse, or any workplace, varies by country and is often governed by OSHA regulations, designed to ensure a safe and healthy working environment. The specifics depend on the type of work being done and the duration of exposure to cold conditions.

In the United States, for example, OSHA doesn’t specify minimum temperature levels but requires employers to provide a workplace free from recognized hazards, which includes protecting workers from extreme cold. Guidelines suggest maintaining a minimum temperature of about 68°F for indoor workplaces involving sedentary work, but this isn’t a legal requirement.

Employers should consult local regulations and guidelines to ensure compliance with legal standards for workplace temperatures, focusing on employee welfare and product storage needs.

Can it be too hot for the warehouse?

Excessive heat in a warehouse can compromise worker safety, damage temperature-sensitive products, and disrupt equipment operations. High temperatures increase the risk of heat stress among employees and can spoil goods, while also potentially leading to equipment failure due to overheating.

Benefits of Efficient Warehouse Temperature Monitoring

Efficient warehouse temperature monitoring devices enhance operational efficiency, product quality, and financial performance. Product integrity is upheld by maintaining optimal temperatures for sensitive items, reducing spoilage. Effective temperature monitoring ensures compliance with regulations, avoiding legal issues and potential fines.Energy efficiency is achieved through optimized temperature control, lowering consumption and costs. Proper temperature management can prevent accidents, hazardous conditions and improve safety within the warehouse.

Modern temperature monitoring systems can provide a wealth of data that can be analyzed to improve operations. This data can help identify trends, pinpoint inefficiencies, and inform decisions about warehouse layout, product placement, and temperature control strategies. Reduced costs result from minimizing product loss and energy savings. Ensuring products are stored and shipped under ideal conditions leads to higher quality goods and increased customer satisfaction. Real-time alerts and automation enable prompt action and efficiency to prevent damage.

Collectively, these advantages make temperature monitoring a crucial part of modern warehouse management, safeguarding products and streamlining operations. Overall, efficient warehouse temperature monitoring is a critical component of modern warehouse management, offering both short-term and long-term benefits by safeguarding product quality, ensuring safety, and optimizing operational efficiency.

Our E-Control Systems real-time monitoring and tailored alerts provide immediate notifications about deviations in temperature, humidity, air quality and energy consumption, allowing for swift actions to mitigate problems and reduce risk. Designed to be scalable and flexible, our solution fits warehouses of every size and layout, efficiently processing extensive data from numerous sensors to meet the diverse requirements of both small and expansive operations. The remote access capability enables authorized users to oversee the warehouse environment from any location with internet access, enhancing the ability to make prompt decisions and interventions.

How many warehouse temperature sensors do I need?

The number of temperature sensors needed in a warehouse varies based on its size, layout, the types of goods stored, and areas prone to temperature fluctuations. Generally, one sensor per 400-500 square feet is recommended, but consider specific storage needs, regulatory requirements, and strategic placement for accurate environmental monitoring.

Does humidity need to be monitored in the warehouse?

A warehouse temperature and humidity monitoring system safeguards product integrity by protecting electronics, pharmaceuticals, and food from damage caused by inappropriate humidity levels. Effective humidity control also prevents corrosion and electrical problems in warehouse equipment, ensuring their longevity. It contributes to worker health by maintaining a comfortable, healthy environment. Regulatory compliance for product storage is another critical aspect addressed by humidity monitoring. It facilitates cost savings by preventing product spoilage and equipment damage. Advanced humidity monitoring systems offer the advantage of real-time alerts, enabling adjustments to maintain optimal conditions. Overall, efficient humidity management preserves product quality, ensuring equipment maintenance, and supports a safe, productive work environment.

Will a wireless temperature monitoring system work in a warehouse?

Our E-Control Systems wireless temperature monitoring systems are highly effective in warehouses. They offer scalable, flexible solutions that easily adapt to different sizes and layouts. Our systems provide real-time monitoring and alerts, support remote access, and require minimal installation efforts, making them suitable and more cost efficient for reliably maintaining optimal temperature conditions in many storage environments.

What are the key benefits of using a warehouse temperature and humidity monitoring system?

Installing a warehouse temperature and humidity monitoring system protects sensitive inventory from environmental damage, providing peace of mind and operational efficiency. If your business stores pharmaceuticals, food products, electronics, or paper goods, minor fluctuations in the temperature can cause spoilage, mold, or corrosion. Instead of depending on manual temperature checks to keep your products safe, automated sensors can measure, collect, and transmit data to a smartphone to prevent expensive disruptions, reducing waste. Warehouse managers can respond quickly to any changes and ensure optimal conditions and regulatory compliance.

How do warehouse temperature control systems differ from basic monitoring solutions?

Warehouse climate control systems go beyond tracking conditions by actively regulating them. Automated control systems report temperature, air quality, and humidity changes in real time by adjusting HVAC levels, triggering ventilation, and activating dehumidifiers. This proactively maintains consistent environmental conditions, using predictive algorithms to anticipate fluctuations and make adjustments before problems occur, unlike passive monitoring that alerts staff only when thresholds are breached.

What types of warehouse temperature monitoring devices are commonly used, and how are they installed?

The most beneficial type of warehouse temperature monitoring device is the wireless sensor node. These compact units are placed strategically inside a facility, mounted on walls or shelving units, to transmit real-time temperature data using Wi-Fi or Bluetooth. Installation includes identifying hot and cold zones and attaching the sensors with adhesive pads or brackets. They’re also easily repositioned if storage layouts change, because they’re wireless. An integrated HVAC monitoring system can also be connected to the warehouse’s heating and cooling infrastructure. HVAC technicians embed the sensors into ductwork or control panels. These systems are suited for large facilities that need strict climate control.

How does warehouse temperature management contribute to regulatory compliance and operational efficiency?

From an operational standpoint, warehouse temperature management supports cost savings and energy efficiency. They comply with regulatory regulations in the food, pharmaceutical, and electronic industries, where products have to be stored within strict temperature ranges for safety and potency. Due to the effectiveness of automated systems, violations can be avoided, reducing the risk of degradation and spoilage, so audits and inspections are smoothly accomplished.

Can warehouse climate control systems scale with my operation as it grows?

Warehouse temperature control systems offer customization and scalability for your business when it grows. They can be programmed for different zones within a warehouse, with different climate needs. Basic monitoring tools may provide useful data, but they lack the precision and responsiveness needed to manage complex storage environments. Our temperature control systems at E-Control Systems work for warehouses of all sizes and configurations, and can manage data from multiple sensors. They can be monitored from anywhere with an internet or cellular connection with their convenient remote access feature from your smartphone.

What maintenance is required for warehouse temperature and humidity monitoring systems?

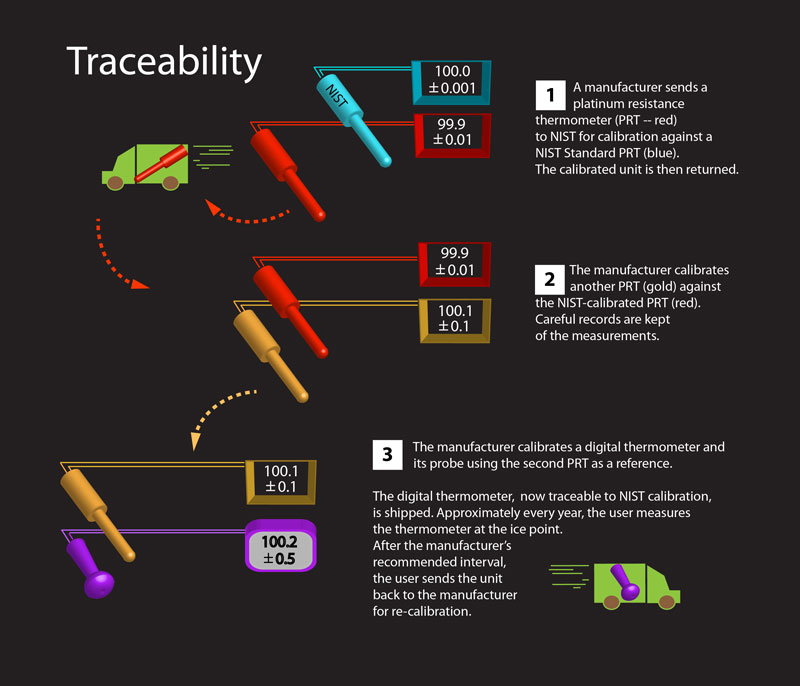

Routine calibration will ensure sensors stay accurate. Environmental conditions can cause minor reading drifts, especially in high-traffic or industrial areas. If small deviations lead to spoilage or compliance issues, regular and remote calibration becomes important. Software updates and security patches will keep your operating smoothly.

How do warehouse temperature monitoring devices handle data during power or connectivity disruptions?

Reliable monitoring devices with multiple sensors are positioned in overlapping zones, while data transmits through Wi-Fi and cellular networks, so if one connection fails, the system automatically changes to the backup. Readings are stored, and restored in the event of a power failure, and reloaded with the history. Alerts and logs continue to flow, even during connectivity disruptions, allowing managers continuous oversight.