Remote Temperature Monitoring Systems For School Cafeterias

A good temperature monitoring system is vital to any school foodservice department. The most important temperatures to monitor include walk-in coolers/freezers, reach-in refrigerators/freezers, milk coolers, holding units, and final rinse temperatures of dish machines. Additionally, food temperature data must be monitored: from receiving, to storage, to holding temperatures, to cooking temperatures.

How E-Control Systems Works for Cafeteria Food Temperature Monitoring

E-Control Systems offers a comprehensive monitoring solution tailored for school environments. Our system uses advanced sensors to continuously monitor critical parameters such as temperature and humidity of various equipment and rooms in schools. Real-time data is collected, analyzed, and displayed on a centralized dashboard, providing instant visibility into the conditions of child nutrition cafeterias, classrooms, laboratories, and other school spaces.

Additionally, E-Control Systems provides proactive management through instant alerts and notifications. When any deviation occurs from the specified range of parameters, designated personnel are promptly alerted, allowing them to take immediate action to ensure a safe and comfortable learning environment for students. The system supports compliance with regulatory requirements by offering detailed documentation, audit logs, and reports, helping schools maintain safety standards and meet health guidelines.

E-Control Systems Features for School

What makes E-Control Systems stand out? Our sensors and intelligates can monitor any aspect of your School business 24/7.

What Sets Our Cafeteria Food Safety Monitoring Apart from Other Options in the Market?

E-Control Systems’ school monitoring solution stands out from other options in the market due to its unique features and capabilities. Our system offers comprehensive monitoring of critical parameters such as temperature and humidity in real-time. It continuously collects data through advanced sensors, providing instant visibility into the conditions of child nutrition cafeterias, classrooms, laboratories, and other school spaces.

Our E-Control Systems solution provides proactive management through customizable alerts and notifications. When any parameter deviates from the desired range, designated personnel are promptly alerted, enabling immediate action to ensure the safety and well-being of students. Additionally, E-Control Systems supports compliance with regulatory requirements by offering detailed documentation, audit logs, and reports, facilitating adherence to safety standards and health guidelines. With its comprehensive monitoring, proactive alerts, and compliance support, our solution provides schools with a reliable and effective tool to ensure a safe and healthy learning environment for students.

Our School Customers Include:

School Cafeteria Temperature Monitoring For Refrigerators, Coolers, and Freezers Monitoring

A good temperature monitoring system is vital to any school food service department. The most important temperatures to monitor include walk-in coolers/freezers, reach-in refrigerators/freezers, milk coolers, holding units, and final rinse temperatures of dish machines. Additionally, food temperature data must be monitored: from receiving, to storage, to holding temperatures, to cooking temperatures.

Gathering and recording temperatures is only one part of the equation. A good temperature monitoring system should also alert you when any of your temperatures fall out of range, and thus help avoid costly product loss. You should be able to view your entire operation from anywhere, at any time and be able to take corrective actions on the spot and print out summary data in the forms of charts and graphs. Having all data readily available at your fingertips will help with HACCP compliance.

HACCP implementation can be a long process with many steps. A temperature monitoring system should help automate all of your HACCP requirements, including logging asset temperature data, food temperature data, and Standard Operating Procedures (SOP).

The USDA released “Guidance for School Food Authorities: Developing a School Food Safety Program Based on the Process Approach to HACCP Principles.” This serves as a guide for Food and Nutrition Service Departments in regard to following HACCP Guidelines.

E-Control Systems has developed a complete solution to meet strict regulatory compliance. The system comes pre-configured with HACCP compliant temperature ranges and can be customized to fit the needs of each individual user. Not only can you monitor the temperatures of all your equipment and food at any time, but the system will send alerts if temperatures fall out of range.

Safe Food Storage in Schools

Perishable foods must be kept in sealed containers and promptly refrigerated before they enter the Temperature Danger Zone (between 4°C and 60°C), which is the temperature range in which bacteria thrive (doubling every four to 20 minutes). High-risk foods like meat, eggs or dairy should never be left at room temperature for too long; after two hours in the danger zone, high-risk foods must be thrown out, and this time is cumulative — so transport, delivery and prep time counts.

Any foods that are on display for self-service should either be packaged in sealed wrapping or should have proper serving utensils like tongs or spoons — students should never have a reason to touch food with their bare hands.

Here are a few helpful reminders about safe food storage and display in educational institutions:

- Raw meat, fish and poultry should be stored on the bottom shelf of the refrigerator, below ready-to-eat foods or fresh produce. Keep it covered with plastic wrap or in sealed containers.

- Dry goods should be stored in sealed packages or containers; store off the ground and away from the wall to deter pests.

- Hot foods should be displayed at 60°C or above — remember to preheat hot holding equipment and make sure that hot food is cooked/reheated to at least 74°C before placing it into hot holding equipment.

- Cold foods should be stored at 4°C or below — it’s all about keeping high-risk foods out of the danger zone!

School Temperature Monitoring FAQ's

What is a school cafeteria temperature monitoring system?

School cafeteria refrigeration monitoring technology systems are designed to maintain food safety by continuously tracking and recording temperatures in food storage areas.

E-Control Systems refrigerator and freezer monitoring systems use advanced sensors to gather real-time data, perform analysis, and present the information on a centralized dashboard, offering instant insights into the conditions of school cafeterias. Our systems provide proactive management by providing instant alerts to designated employees and notifications if temperatures exceed safe thresholds, enabling prompt corrective actions to ensure a safe environment. Supporting regulatory compliance, the systems include comprehensive documentation, audit logs, and reports, assisting schools in maintaining safety standards and meeting health guidelines effectively.

School cafeteria temperature monitoring systems are important to safeguard against foodborne illnesses, ensure perishable items are stored and handled at appropriate temperatures, and maintain compliance with health standards.

Why do I need a school temperature monitoring system for freezers, coolers, and refrigerators?

School cafeteria freezer monitoring systems and those for refrigerators and coolers are essential for food safety to ensure perishable items in school cafeterias are consistently stored at safe temperatures, reducing the risk of foodborne illnesses. They help schools comply with health regulations and food safety standards, because these require monitoring and documenting temperature data. By promptly detecting temperature fluctuations or equipment malfunctions, the system enables corrective actions and prevents food spoilage and waste, which can result in cost savings for the school. Maintaining proper food storage and safety practices provides peace of mind by continuously monitoring food storage areas, reducing the chances of unexpected issues arising.

Cafeteria Walk-In Temperature Monitoring Process

The process of cafeteria walk-in temperature monitoring in freezers and refrigerators involves a series of steps to ensure that food items are stored at safe and consistent temperatures. Here's a typical process for monitoring temperatures in walk-in refrigerators and freezers in a cafeteria:

- Installation of Temperature Sensors: Temperature sensors or probes are strategically placed inside the walk-in refrigerators and freezers. These sensors continuously measure the temperature and transmit the data to a central monitoring unit.

- Central Monitoring Unit: A central monitoring unit is typically located in a control room or office. This unit collects data from the sensors in real time.

- Setting Temperature Thresholds: Safe temperature ranges for refrigerators and freezers are defined according to food safety guidelines and regulations. These temperature thresholds are programmed into the monitoring system.

- Real-time Monitoring: The monitoring system continuously checks the temperature readings from the sensors against the predefined thresholds. If temperatures fall outside the safe range, the system triggers alerts.

- Alerts and Notifications: When the system detects temperature deviations, it sends alerts and notifications to designated personnel through various means, such as emails, text messages, or audible alarms.

- Immediate Response: Upon receiving an alert, cafeteria staff or administrators can take immediate corrective actions. This may include adjusting the thermostat settings, inspecting the equipment for malfunctions, or relocating food items to a different storage unit.

- Data Logging: The monitoring system records and logs temperature data over time. This historical data is crucial for compliance reporting, trend analysis, and identifying recurring issues.

- Compliance Reports: The system can generate reports that demonstrate compliance with food safety regulations. These reports are often required during health inspections and audits.

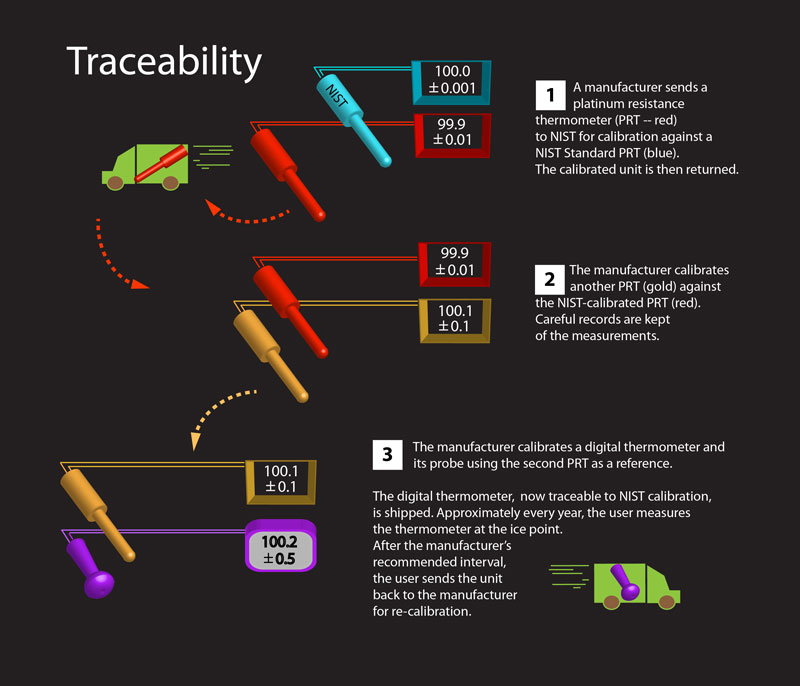

- Regular Maintenance: Periodic maintenance and calibration of temperature sensors and monitoring equipment are essential to ensure accurate and reliable readings.

- Training: Cafeteria staff should be trained on how to use the monitoring system effectively, how to respond to alerts and proper food safety practices.

- Documentation: All temperature monitoring activities, including alert responses and equipment maintenance, should be documented for record-keeping purposes.

By following this process, cafeteria personnel can maintain the safety and quality of food items stored in walk-in refrigerators and freezers, reduce the risk of foodborne illnesses, and ensure compliance with food safety regulations.

What are the types of school temperature sensors?

The process of cafeteria walk-in temperature monitoring technology in freezers and refrigerators involves a series of steps to ensure that food items are stored at safe and consistent temperatures. Here's a typical process for monitoring temperatures in walk-in refrigerators and freezers in a cafeteria:

- Installation of Temperature Sensors: Temperature sensors or probes are strategically placed inside the walk-in refrigerators and freezers. These sensors continuously measure the temperature and transmit the data to a central monitoring unit.

- Central Monitoring Unit: A central monitoring unit is typically located in a control room or office. This unit collects data from the sensors in real time.

- Setting Temperature Thresholds: Safe temperature ranges for refrigerators and freezers are defined according to food safety guidelines and regulations. These temperature thresholds are programmed into the monitoring system.

- Real-time Monitoring: The monitoring system continuously checks the temperature readings from the sensors against the predefined thresholds. If temperatures fall outside the safe range, the system triggers alerts.

- Alerts and Notifications: When the system detects temperature deviations, it sends alerts and notifications to designated personnel through various means, such as emails, text messages, or audible alarms.

- Immediate Response: Upon receiving an alert, cafeteria staff or administrators can take immediate corrective actions. This may include adjusting the thermostat settings, inspecting the equipment for malfunctions, or relocating food items to a different storage unit.

- Data Logging: The monitoring system records and logs temperature data over time. This historical data is crucial for compliance reporting, trend analysis, and identifying recurring issues.

- Compliance Reports: The system can generate reports that demonstrate compliance with food safety regulations. These reports are often required during health inspections and audits.

- Regular Maintenance: Periodic maintenance and calibration of temperature sensors and monitoring equipment are essential to ensure accurate and reliable readings.

- Training: Cafeteria staff should be trained on how to use the monitoring system effectively, how to respond to alerts and proper food safety practices.

- Documentation: All temperature monitoring activities, including alert responses and equipment maintenance, should be documented for record-keeping purposes.

By following this process, cafeteria personnel can maintain the safety and quality of food items stored in walk-in refrigerators and freezers, reduce the risk of foodborne illnesses, and ensure compliance with food safety regulations.

How much does a school temperature monitoring system cost?

The cost of a school temperature monitoring system can vary based on factors like system complexity, the number of sensors needed, installation and setup requirements, ongoing maintenance, and additional features. A basic system for a small school cafeteria with a few refrigerators and freezers might range from a few hundred to a few thousand dollars, excluding maintenance costs. The system is scalable, so once the initial system is in place, it can be expanded to monitor additional refrigerators and freezers at any time, for a nominal cost. Consideration should also be given to brand choices and the presence of subscription fees for cloud-based monitoring. To get an accurate estimate, request a quote based on your specific school cafeteria's needs and budget, keeping in mind the long-term benefits of investing in food safety and compliance.

How does the school cafeteria food safety monitor ensure data is not lost during a Wi-Fi outage?

During Wi-Fi blackouts, a school cafeteria food safety monitor uses internal storage to save data offline, capturing any temperature change, even if an outage occurs. As soon as Wi-Fi service resumes, the system saves the information in the cloud dashboard. This reliable backup ensures no data is lost, so the school can still pass audits and meet required health standards.

Can remote temperature monitoring in schools be used for kitchen equipment maintenance?

Remote temperature monitoring systems in schools keep a digital log that can reveal patterns if refrigerators, coolers, or freezers may be starting to fail, because they can access a clear history. Staff will be alerted if temperatures deviate, and they can schedule maintenance and repair to extend the life of the equipment so food is always kept at safe temperatures.

How quickly does the cafeteria food temp alert system notify staff of an unsafe temperature?

E- Control Systems sensors on monitoring systems provide cafeteria food temp alerts, sending real-time notifications to a phone, pager, via SMS, or an app so kitchen staff can address issues if cold storage fails, to prevent foodborne illnesses.

Is the cafeteria freezer monitoring technology scalable for multiple school district locations?

Cafeteria freezer monitoring technology can handle multiple school district locations using scalable wireless networks and shared software that supports many sensors. It connects all the schools into a centralized dashboard, with the ability to expand even after the initial system is installed, making it convenient when the district adds new schools.

Are the wireless sensors safe and easy to install on existing school refrigeration equipment?

Wireless sensors for remote temperature monitoring systems in schools can be safely, quickly, and easily installed on existing kitchen equipment like refrigerators and freezers. You can stick them on with double sided tape, velcro, or clips, and connect them wirelessly in school cafeterias to support food safety without disrupting cafeteria kitchen workflow.

How does remote temperature monitoring in schools eliminate the need for paper HACCP logs?

Remote temperature monitoring systems in schools replace the need to manually complete HACCP logs because they continuously record, timestamp, and save temperature data from food storage equipment into an accessible digital database. When temperatures fall out of safe ranges, alerts are sent through the app or by text. Instead of filling out paper logs manually, staff can monitor equipment performance and food safety records on the school’s digital dashboard, ensuring the school complies with HACCP safety requirements.

Does the cafeteria refrigeration monitoring technology support cook/chill or reheating SOPs?

Using school cafeteria cooler monitoring technology, automates cook/chill and reheating Standard Operating Procedures, by continuously recording food storage conditions. It prevents bacteria from growing because it verifies that reheated foods achieve the required heat levels before food is served. It also ensures that food cooled after cooking reaches a safe holding temperature. This technology ensures cafeteria food doesn’t spoil and that schools have a reliable record when health inspections occur.