HACCP Based Standard Operating Procedure (SOP)

All food service operations must develop a food safety program. A HACCP requirement for developing a comprehensive program includes developing, documenting, and implementing Standard Operating Procedures (SOP).

Food Service & Restaurant Standard Operating Procedures

All food service operations must develop a food safety program. A HACCP requirement for developing a comprehensive program includes developing, documenting, and implementing Standard Operating Procedures (SOP) and compliance.

According to the Guidance for School Food Authorities released by the USDA, “SOPs lay a strong foundation for your overall school food safety program. SOPs are step-by-step written instructions for routine food service tasks that affect the safety of food (‘nonspecific’ hazards), such as proper dishwashing procedures, or for tasks that are a part of the HACCP-based plan (specific hazards), such as proper cooking procedures. Each SOP should include instructions on monitoring, documentation, corrective actions, and periodic review of the procedures they cover. Adherence to SOPs allows food service managers and employees to effectively control and prevent hazards.”

The School Food Authorities (SFA) may develop and have their own SOPs in place. However, if they do not, the USDA developed a series of SOPs that they posted on the National Food Service Management Institute’s (NFSMI) website.

The main categories of SOPs are:

- General Safety Considerations

- Personnel

- Product Procurement

- Receiving

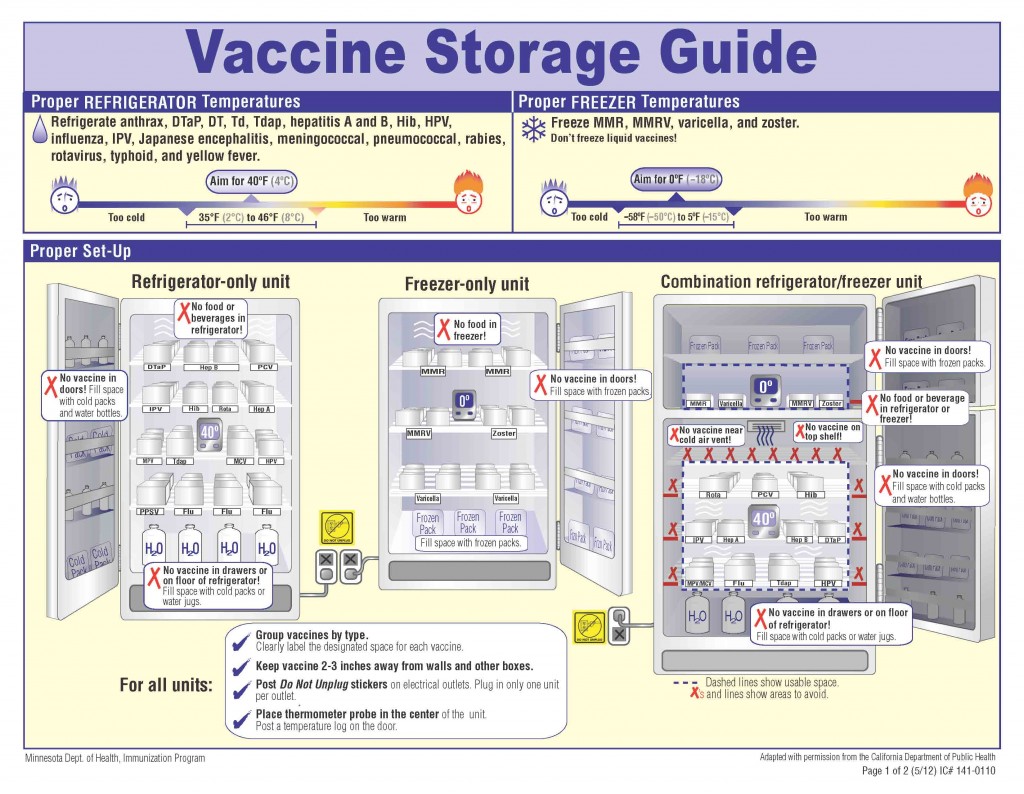

- Storing

- Transporting

- Holding

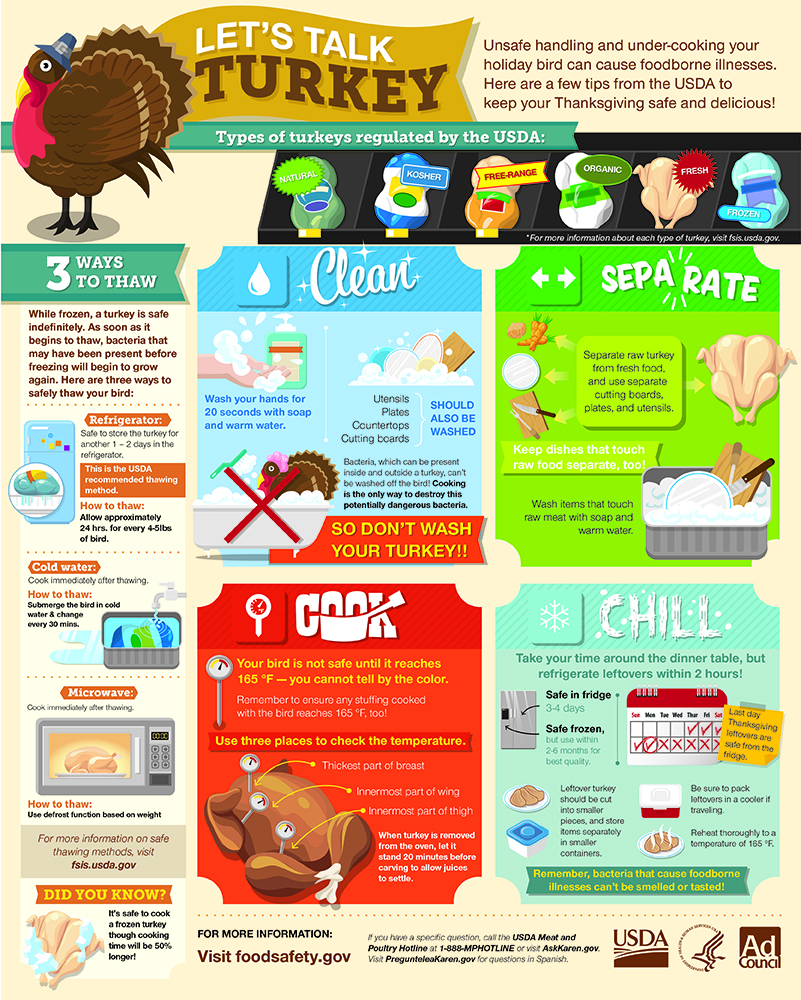

- Preparation

- Cleaning/Sanitizing

- Cooking and Documenting Temperatures

- Cooling

- Reheating

All applicable SOPs should be followed for the preparation and service of all menu items. The USDA is developing additional SOPs to be used specifically for food preparation in schools. These SOPs include critical limits, as well as monitoring, corrective action, verification, and recordkeeping procedures.

Foodservice operations must establish monitoring procedures. SOPs must be monitored, controlled, and documented, in writing, in order to help immediately recognize when a control point is out of range, so that a corrective action may be taken. The SOPs will establish what corrective actions should be taken, thereby averting any possible HACCP violations.

All SOP guidelines should be reviewed on an annual basis.

To see how you can automate your SOP requirements, checkout E-Control Systems’ IntelliCheck™ – HACCP Inspection System. The IntelliCheck™ system works in conjunction with our stainless steel temperature probe to get accurate readings of all your critical control points. Simply insert the probe into any of your food items and get an instant reading that will be logged in real time. With our patent pending IntelliCheck™ technology, corrective actions and other preventative maintenance may be taken directly from your iOS device. No more filling out checklists by hand and stuffing them into a filing cabinet. With IntelliCheck™, you simply choose an option on your touchscreen and the system does the rest.

HACCP Standard Operating Procedure FAQ's

What Is HACCP, and Why Is It Important for Food Safety?

HACCP-Based Standard Operating Procedures (SOPs) are important guidelines that maintain food safety in food production facilities as well as commercial kitchens. They ensure best practices are used for sanitation, storage, temperature control, and contamination to prevent potential foodborne illnesses so businesses comply with health and safety regulations.

What Are the Five Parts of SOP?

HACCP-Based SOPs ensure food safety by integrating these 5 components:

- Identify Hazards: Recognize biological, chemical, and physical risks in food handling and processing.

- Determine Critical Control Points: Pinpoint key stages where hazards can be controlled or eliminated.

- Monitor Procedures: Track food safety measures like temperature and sanitation.

- Implement Corrective Measures: Address deviations to limit food safety risks and maintain standards.

- Maintain Records: Document processes to ensure HACCP and SOP compliance.

What Is an SOP Checklist?

An SOP checklist is a guide that employees consistently follow that lists accurate, systematic procedures. SOP checklists streamline operations in industries where it's important to comply with regulations, such as healthcare, manufacturing, and food safety. These checklists also help organizations increase productivity and maintain quality control. They minimize risks and errors and prevent inconsistencies. HACCP SOPs can be automated, conveniently monitored, and corrected using an IOS device touchscreen with our E-Control Systems IntelliCheck HACCP inspection system, which works together with our E-Control stainless steel temperature probe to ensure accurate critical control point readings.

What Does a Good SOP Look Like?

An effective SOP is easy to understand and follow, with clear and concise instructions. It eliminates any ambiguity because it uses straightforward language and recommends a logical sequence of steps to complete tasks. It should also detail required safety measures, include checkpoints for quality control, reduce or eliminate any errors, and improve workplace efficiency. An effective, well-documented SOP makes sure employees know and understand expectations to execute tasks properly and meet industry standards.

How Often Should HACCP-Based SOPs Be Reviewed and Updated?

HACCP-based Standard Operating Procedures (SOPs) should be reviewed annually to ensure its procedures are current and reflect any changes that need to be implemented in processes, ingredients, equipment, methods, or safety standards. Make adjustments to your SOP when guidelines change and update it when new hazards are identified, when official requirements change, or when customers have complaints. This will ensure your business procedures are safe and consistent.

Can HACCP-Based SOPs Be Used in Non-Food Industries?

While HACCP is commonly used in industries where food safety compliance is important, non-food industries are increasingly using it more often to improve safety and make their operations more efficient. Sectors including pharmaceuticals, cosmetics, water treatment, medical device production, and chemical manufacturing use HACCP SOPs to identify hazards, implement proper procedures, and maintain high safety standards. They help businesses assess risks and ensure consistency while protecting consumers.

Related Topics

- Proper Food Cooling Process

- Food Storage Guidelines for Restaurants

- Food Service Temperature Monitoring Systems

- Importance of Temperature Control in the Food Industry

- Food Safety Operations

- Food Service Temperature Monitoring

- Food Safety Issues in Restaurants

- Food Safety Inspection Tools

- HARPC vs. HAACP

- Why Are Restaurants So Cold?