Wireless Life Sciences Temperature & Humidity Control Systems

Your 24/7 Wireless Temperature Monitoring Solution

Vaccine effectiveness can decrease by 15-35% if not stored at recommended temperatures. 0

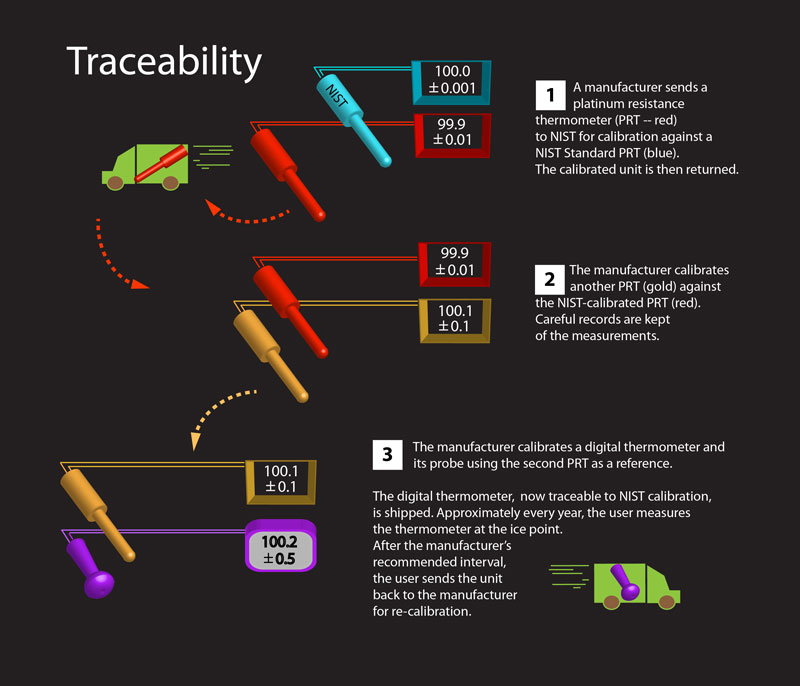

E-Control Systems (ECS) offers a complete IoT based temperature monitoring solution for the life science industry. Our fully automated enterprise-wide solution makes it easy to monitor your entire life science operation, so that you can focus on patient care, instead of manually logging critical data that is needed to comply with many standards, including: The Joint Commission, AABB, GMP, FCC, Vaccines for Children (VFC), and FDA. NIST Traceable Calibration and re-calibration is available directly from the factory, or on-site.

44% of labs do not have a temperature monitoring system in place.

How E-Control Systems Works for Life Sciences Temperature & Humidity Control

E-Control Systems (ECS) works for life sciences by offering a completely wireless temperature monitoring solution for the Lab and life sciences industry. Life science industries can include:

- Laboratories

- Pharmacies

- Calibration laboratories

- Vaccine Storage

- Hospitals

- Biobanks, blood and tissue Storage

- Clinical trials and R&D

- Ambient Temperature

- Clean Rooms

- Warehouses and distribution centers

- Refrigerated Trucks

- And more…

Our fully automated enterprise-wide solution makes it easy to monitor your entire life science operation, so that you can focus on patient care, research, and testing. Forget about the burdensome task of manually logging critical data that is required to comply with many standards including: The Joint Commission, AABB, GLP/GMP, FCC, Vaccines for Children (VFC), and FDA.

Take compliance to the next level while protecting assets and stakeholders and streamlining your life sciences business. Keep reading to learn more about E-Control Systems, and how we can work for life science companies.

E-Control Systems Features for Life Sciences

What makes E-Control Systems stand out? Our sensors and Intelligates can monitor any aspect of your lab 24/7.

What Sets Our Life Sciences Temperature Control Systems Apart from Other Options in the Market?

What sets our life sciences system apart from other available options is our Intellisense™ family of products being at the core of everything we do. With this in mind, ECS utilizes our Patented Intelligent Sensors (U.S. patent no. 9,064,389) AND the free ECS app, which is compatible for all iOS Apple and Android devices.

From the app, you can effectively monitor all of your equipment all day, every day! Without missing a beat, you can receive alerts and notifications if your equipment’s readings are ever misaligned. Before any critical failures arise, the system will notify you immediately. This allows facilities to take effective measures faster, which can save you from losing inventory, capital, and years of research and effort. Thus helping support the mission and importance of timeliness life science companies chase every day.

Not to mention, our wireless temperature monitoring solutions address an array of critical pain points that include, but aren’t limited to:

- Humidity

- CO2

- Ultra-low temperature freezers (ULT)

- Liquid nitrogen tanks (LN2)

- Compressor runtimes

- Refrigerant leaks

- Dishwasher final rinse

- Power interruption

Here at ECS, our team of engineers and professionals are able to think outside of the box and create custom solutions to meet the needs of life science businesses. Learn more and download the ECS brochure.

Our Life Science Customers Include:

Life Sciences Environmental Monitoring Systems

Schools, Universities, Processing Plants, Restaurants & More

Our IntelliSense™ Wireless Temperature Monitoring System enables you to monitor all of your cabinet/equipment temperatures and other critical control points required for HACCP record keeping. Using our Patented Intelligent Sensor (U.S. Patent No. 9,064,389) and our free App for your iOS Apple and Android devices, you will be able to automatically and effortlessly monitor all of your equipment 24 hours a day, 7 days a week and receive alerts should any of your equipment readings fall out of range.

With ECS, you have the flexibility to monitor a wide array of items based on your custom applications, including but not limited to:

- Walk-In Coolers/Freezers

- Reach-in Coolers/Freezers

- Milk Coolers

- Holding Units (Hot & Cold)

- Under Counter Units

- Dishwasher Final Rinse Temperature

- Dry Storage

- Cold Storage

- Power Interruption

- Cook/Chill Units

- Food Temperatures

- Oven Temperatures

A variety of sensor types allows you to monitor not only temperatures but also humidity, door status, and other critical points. All data is stored in our secure cloud with server redundancy and automated system backups. Each sensor comes standard with data loggers, which will store data in case of a network or power outage. As soon as network/power is restored, the data loggers will transmit all of the data to the system. The system is battery-operated using wireless sensors that are easily installed, cost effective, and allow you to get up and running quickly.

Life Science FAQ's

Why is environmental control important for life sciences?

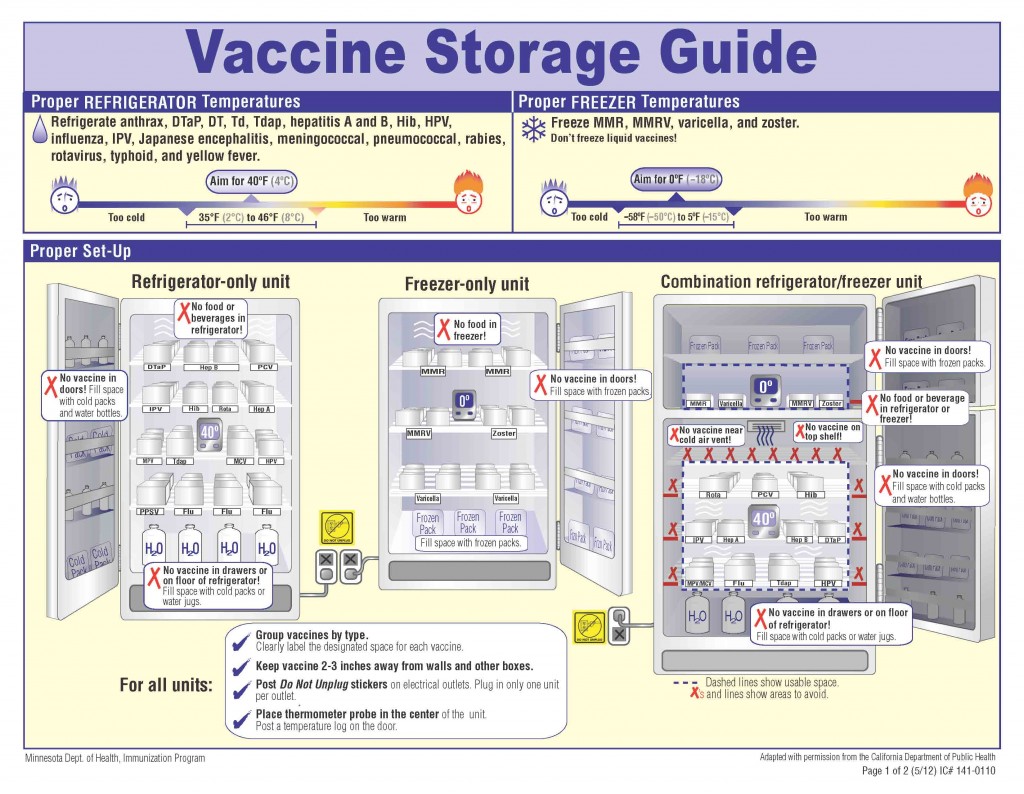

For the life science and Lab industries, managing the environment is imperative. Keeping precise temperatures, humidity levels, and other parameters can ensure the stored products, like critical vaccines, remain effective. ECS has been working with various vaccine manufactures and the CDC to help our suite of products maximize their potential. From this experience, our software has built in analytics to measure all necessary environmental parameters to ensure product efficacy and sustainability.

Here at ECS, we use NIST calibrated probes in glycol and special probes specifically designed for ultra low temperatures to provide accurate and precise temperature readings. In the life science industry, accuracy and precision can be a make or break situation. Each piece of ECS hardware includes a datalogger incorporated to make sure the temperature is consistently accounted for and measured. So you’re never missing a beat throughout the ENTIRE cold chain.

Don’t leave anything to chance. ECS can be your perfect temperature regulation solution.

Are there risks in life science settings if temperature is NOT monitored?

Did you know that roughly 44% of labs don’t have a temperature monitoring system? Meaning that almost half of labs are assuming the risks associated with mismanagement of temperature regulation.

Monitoring temperature and other critical environmental influences has become a growing need for many life science industries. To address this, ECS has evolved into a full-service monitoring solution. ECS innovations and solutions are designed to meet the ever-changing market needs and constantly evolving regulatory requirements related to food, drug, and manufacturing processes and controls. These manufacturing processes and controls can include HACCP, the Joint Commission, AABB, GLP/GMP, FCC, and FDA.

If you need to keep all laboratory specimens or products in a monitored environment to sustain their potency, temperature monitoring is a daily responsibility. The CDC highly recommends logging lab refrigerator and freezer temperatures at least twice a day. Malfunctions and environmental disruptions can be a constant risk, so incorporating a system to record temperatures is absolutely necessary as an added fail safe.

Utilizing our temperature monitoring solution and taking advantage of our mobile application can not only keep you from losing your valuable materials or products, but also helps protect time and money investments too. Furthermore, it supports your ability to serve patients and customers, thus potentially saving or significantly impacting lives.

There isn’t a universal temperature for biological materials, samples, or vaccines. The necessary stored temperature requirements can vary depending on what you’re storing. Monitoring your life science items through detailed recordings and logged data enables your facility to know actual sample temperatures.

At the start and end of each work day, you can record the minimum and maximum temperature. If temperatures or other environmental factors, like humidity or CO2 levels, aren’t where they should be, you’ll need to take immediate action. Afterall, there is no such thing as caring too much about your units’ content. Being able to frequently check your systems with ECS can put your mind at ease while minimizing risks.

What are the different types of alerts I can set up for life sciences?

Once you’ve mounted your IntelliSensor on your equipment that requires monitoring and plugged in the IntelliGate, you can start to view your data and receive alerts in real-time. From the receipt, you can also print customizable reports.

Your data can be viewed from anywhere and at any time! From the collected data, you can receive alerts via text, email, or through notifications from the easy to use app. Our system also comes with an Asset Management Module, which allows you to manage your equipment and set up preventative maintenance alerts.

With our hosted solution in the cloud, all of your logged data is stored securely in the cloud and available for you to access 24/7 with the help of any computer, smart phone, or tablet. The ECS cloud means you never have to worry about costly server space, server space malfunctions, or upgrade your software.

ECS not only acts as an extra set of eyes for you, the system can safely track and record data AND notify you immediately if anything goes array.

What are the benefits of life science temperature and humidity control?

Life science industries require precise control of atmospheric conditions, including temperature and humidity. This type of monitoring is essential to keep facilities running safely and efficiently. The main benefits for monitoring atmospheric conditions can include:

- Airborne infection control. Regulating humidity and temperature ensures aerosols and other hazardous airborne materials cannot spread as easily. Proper humidity control is essential to the wellbeing of facility workers as well.

- Equipment protection. Proper environmental regulation protects sensitive equipment from electrostatic discharges, and also reduces the risk of damage from excessive moisture buildup on the equipment.

- Data accuracy. Lab data is directly tied to the source material that you’re examining and regulating. If the humidity and temperatures are either too low or too high, it can cause negative effects and possibly result in inaccurate results.<

- Energy efficiency. Equipment in life science facilities are abundant. With that, the power needed to run these types of facilities can be immense. Regulating and monitoring the temperature and humidity can help with a facility's energy consumption. This can lead to reduced energy and saving facilities valuable resources.

ECS can offer you and your facility a turnkey solution which guarantees that valuable data will be transmitted to your network, before our installer leaves the site. Additionally, ECS features and benefits include cell Phone Alerts, fusionLive Dashboard, 24/7 Continuous Monitoring, and daily summaries. The easy to use ECS solution is fully functional and accessible on any device. Enjoy the exceptionally designed interface of ECS and ensure your facility is securely monitored.

Is temperature monitoring a legal requirement for life sciences?

Today, temperature monitoring equipment can be affordable and easily accessible with the help of ESC. The CDC mentions that temperature monitoring systems are like insurance for your facility, and could possibly be the best protection for your vaccines and samples.

If you don't have a temperature monitoring system, now can be the perfect time to get one with ECS. If you're in the food service, healthcare, life science, or retail industry a temperature monitoring system can be absolutely essential for your operation. Many companies rely on a temperature monitoring system to uphold quality assurance, maintain operational efficiency, or meet regulatory compliance. In some cases, legal requirements exist, enacting the need for life science companies to maintain temperature records.

Facilities handling vaccines, pharmaceuticals, tissue samples and other medical assets that must remain at certain temperatures need to follow best practices for storage. Inventory must be in compliance with regulations and these must be proved when audited. Proper storage is critical for these items, and loss of potency due to improper temperatures can reduce the safety and efficacy of the assets.

A temperature monitoring system that includes a data logger solves these issues. Data is automatically stored that personnel can download, print and export for use in reports for internal and external regulators.

With ECS, you have the flexibility to monitor a wide array of items based on your custom application. Operate with integrity when you invest in sophisticated temperature monitoring systems, not just for compliance reasons, but with the care to run the best establishment possible.

What types of life sciences temp sensor technology are used in ultra-low freezers (ULT)?

Internal RTDs, thermocouples, and semiconductor sensors are used to run ultra-low freezers, but don’t provide audit trails for FDA compliance, which are important in the pharmaceutical life sciences and research industries. E-control Systems wireless IntelliSensors monitor life science temperature control, humidity, door openings, power levels, and equipment performance. Patented Intellisensors send real-time alerts and provide continuous data tracking to protect sensitive biological material and vaccines and keep them at –80°C.

Does your life science environmental control system offer mapping and validation services (IQ OQ PQ)?

E‑Control Systems supports its monitoring technology with comprehensive IQ (Installation Qualification), OQ ( Operational Qualification), and PQ (Performance Qualification) to confirm its accurate, compliant and reliable for a life science operation with professional mapping and validation support. This ensures your temperature and humidity monitoring system is working properly in your freezer, fridge, or warehouse, identifying hot or cold spots, so they can be adjusted, and you don’t lose valuable inventory. Too much or too little humidity or temperature can disrupt controlled conditions, impacting stored pharmaceuticals and materials, and producing unreliable or inaccurate scientific results.

How are wireless sensors integrated into existing Building Management Systems (BMS)?

Adding wireless sensors and connecting them to a Building Management System enables them to send data through an existing control hub that translates sensor signals into a format the BMS can read. Once linked to the hub, the BMS monitors humidity, analyzes trends, triggers alarms, or adjusts temperature controls based on incoming data. The sensors allow facilities to upgrade and expand their monitoring capabilities without disrupting current operations.

Why is redundant monitoring important for life science humidity control in a pharmaceutical warehouse?

Redundancy matters in life science storage environments because life science humidity control must be precise and uninterrupted. Any spike can damage sensitive biomedical products, compromising stability or violating official regulatory standards. Multiple sensors function as a safety net, so if one fails or isn’t properly calibrated, another one provides accurate temperature and humidity ratings. This dual verification system keeps life sciences temperature and humidity control consistent in pharmaceutical warehouses and helps avoid product loss.

How does automated monitoring for life sciences assist with FDA 21 CFR Part 11 compliance?

For organizations required to comply with FDA 21 CFR Part 11, automated monitoring systems simplify compliance by replacing manual logs with validated digital records that meet FDA standards and can’t be altered without detection. They log who accessed the system, any actions that were taken, and when environmental conditions changed. This documentation supports accuracy, transparency, and reliable oversight.

How does your automated monitoring for life sciences handle a temperature excursion event?

During a temperature excursion event, automated monitoring detects the deviation and sends an alert to designated employees using the dashboard, email, or text. It captures data before, during, and after the excursion, providing information about what happened. With instant visibility and an audit trail, it supports corrective actions and strengthens temperature control for life sciences.