Oven Temperature Monitoring Systems

How E-Control Works for Oven Control Systems

E-Control Systems offers effective solutions for monitoring and controlling ovens, ensuring optimal cooking conditions and food safety. Our system uses wireless sensors placed within the oven to monitor key parameters such as temperature, cooking time, and internal food temperature in real-time.

The collected data is transmitted to a centralized system for analysis and action. If any deviations from the desired cooking conditions are detected, E-Control Systems triggers instant alerts via email, SMS, or mobile app notifications. This enables prompt intervention to adjust temperature settings or cooking times, ensuring that food is cooked thoroughly and meets quality and safety standards. With its real-time monitoring and instant alert capabilities, E-Control Systems provides a reliable solution for maintaining precise control over oven operations.

E-Control Systems Features for Oven Temperature Control

What makes E-Control Systems stand out? Our sensors and intelligates can monitor any aspect of your Ovens business 24/7.

What Sets Our Wireless Oven Monitoring Apart from Other Options in the Market?

E-Control Systems stands out in the market for oven monitoring due to its reliability and comprehensive features. Our system utilizes wireless sensors placed within the oven to monitor key parameters such as temperature, cooking time, and internal food temperature in real-time. The system’s ability to track these parameters ensures precise control over cooking processes, leading to consistent and high-quality results.

What sets our oven monitoring solution apart is its advanced alert system and data logging capabilities. E-Control Systems triggers instant alerts via email, SMS, or mobile app notifications in case of any deviations from the desired cooking conditions. This enables immediate action to adjust temperature settings or cooking times, preventing undercooking or overcooking of food. Furthermore, our comprehensive data logging and reporting features provide a historical record of oven performance, allowing for analysis, optimization, and compliance with quality standards. With its reliability, advanced alert system, and data-driven insights, E-Control Systems offers a top-tier solution for monitoring and controlling ovens.

Our Ovens Customers Include:

Wireless Oven Control System for Cooking and Food Safety

Oven Temperature Monitoring FAQ's

What is oven temperature mapping, and why is it important?

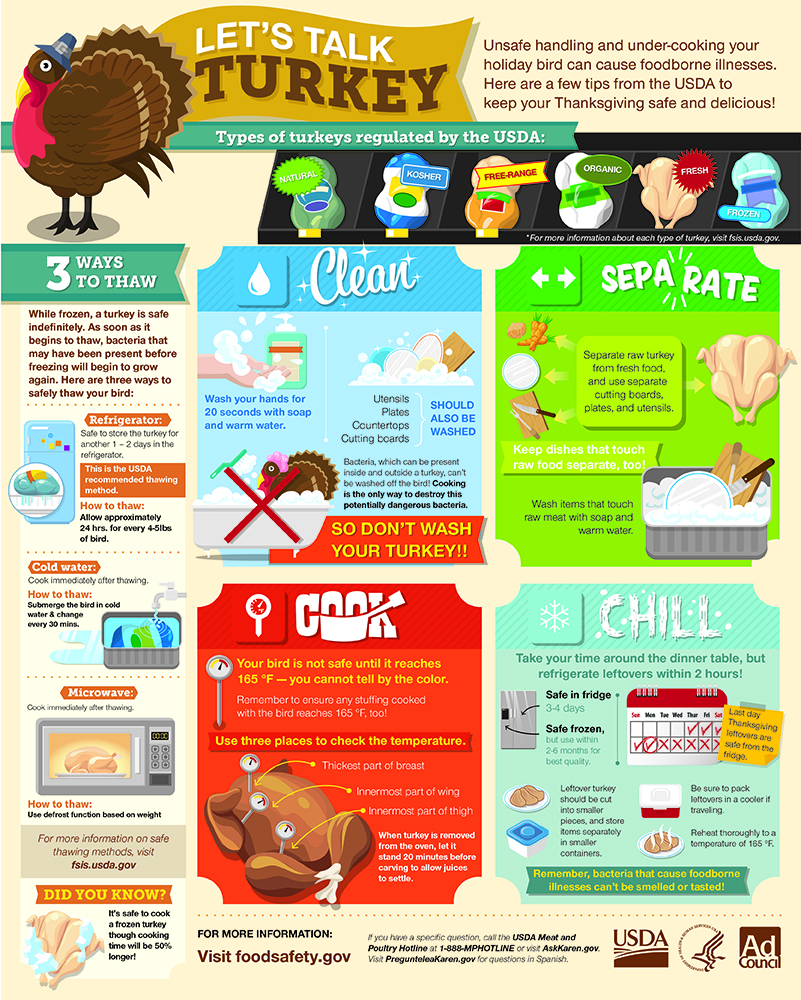

Oven temperature mapping is used to determine if heat is evenly distributed inside an oven. Wireless sensors are positioned carefully inside the oven to measure and log temperature variations. This is important because, without it, uneven heating can cause foods to be undercooked. It's critical in the food industry, where thermal deviations can affect the quality and safety of food, and oven temperature monitoring systems also maintain compliance with regulations.

How does an oven temperature monitoring system differ from a simple thermometer?

Regular thermometers provide a temperature reading for one specific area; an oven temperature monitoring system includes multi-point tracking and data logging to detect fluctuations and cooking temperature irregularities. In regulated food processing environments, a reliable oven temperature monitoring system delivers real-time data and alerts that help confirm uniform heat distribution in different zones, making it easier to detect and correct any temperature deviations. Basic thermometers can’t perform these valuable functions.

Can I retrofit my existing ovens with a stove monitoring device or oven temperature controller?

If you need to upgrade your oven and don’t want to purchase a new one, you can usually integrate a stove monitoring device or oven controller into your existing equipment if your oven supports sensor placement and external connections. These practical add-ons monitor heat distribution, log temperature data, and automate adjustments. Retrofitting ovens allows them to meet modern compliance standards so they’re safe and provide more consistent temperatures.

What kinds of data does an industrial oven temperature recorder capture?

ones inside the oven. It measures how long ovens stay at the proper temperature, how stable the heat is in the oven, and whether some areas reach a hotter or cooler temperature than others. When an industrial oven temperature recorder is in use, it can help workers catch issues early, make adjustments, and ensure products are safe and effective. The recorded data highlights any imbalances or fluctuations that could potentially affect performance. Using the recorded information, employees can make necessary adjustments and keep products safe and reliable. It's also valuable for meeting official regulatory requirements in industries like food processing, aerospace, and pharmaceuticals, where precision heating is critical.

How do alerts and alarms work in an oven temperature monitoring system?

When oven conditions deviate from desired parameters, E-Control Systems' temperature monitoring system records any changes and alerts staff via email, text, or app notifications so they can adjust the temperature or cooking times, preventing uneven and undercooked food, while ensuring food stays safe.

How accurate is an industrial oven temperature recorder?

E-Control Systems Industrial oven temperature recorders are engineered for high performance under conditions that include high temperatures and humidity, even in demanding environments. Our recorders use technology that is widely trusted in the industry for accurate thermal control that’s consistent and reliable. Convenient alerts instantly notify users of temperature deviations through email, text, or mobile app, so temperatures and cooking times can be fine-tuned.

What compliance or regulatory benefits does oven temperature monitoring offer?

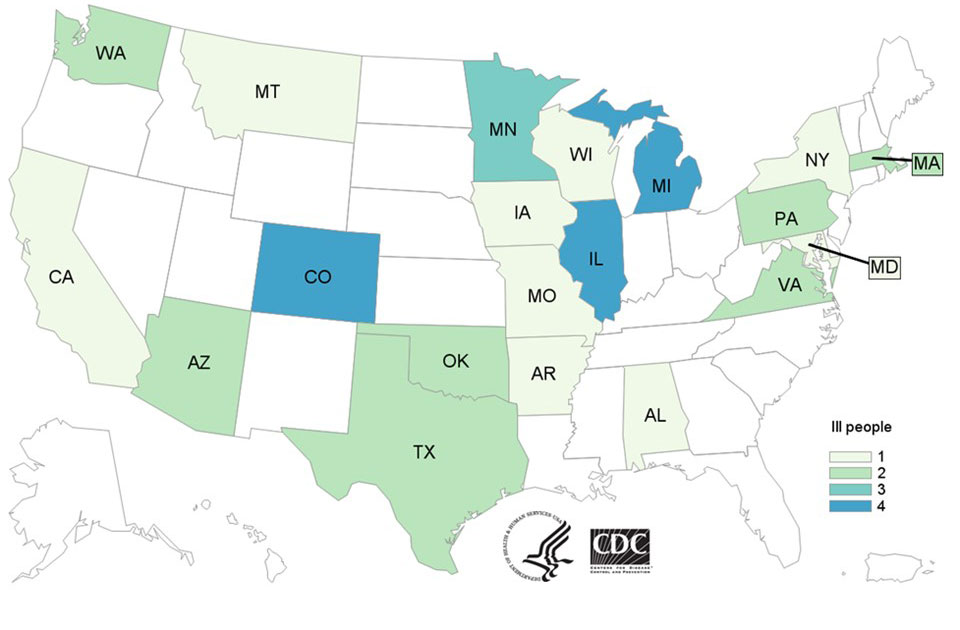

Accurate oven temperature recordings and alerts allow workers to adjust cooking temperatures and timing so microorganisms won't contaminate food or cause foodborne illnesses. Because they have the capability of generating alerts and logging reliable data, E-Control temperature monitoring systems can help businesses comply with FDA food safety regulations while protecting consumer health.