What is Calibration in the Laboratory?

Importance of Equipment Calibration In Science & Medical Labs

Proper instrument calibration can be looked at as the foundation of all laboratory patient testing. Proper calibration is the first step to producing reliable results and assuring good instrument performance. For this reason laboratories should always ensure proper calibration. It establishes a reference point that helps assist instruments to produce accurate testing results. All instruments of measurement, no matter what they measure, require periodic calibration. Even non-laboratory items, such as scales for food preparation, require periodic calibration.

It’s also very important to know when to recalibrate. To ensure your instrument is establishing a reliable baseline and you are building a strong foundation for accurate results. This is why frequent recalibration is recommended.

Types of Calibration

Different types of calibration are suited to specific laboratory instruments, each critical for maintaining rigorous standards. Volume calibration is necessary for pipettes, burettes, and flasks to ensure precise liquid measurement, crucial in chemistry and biology experiments. Weight calibration involves checking the accuracy of balances and scales, which is important in almost every scientific field for precise measurement of substances. Each calibration type targets specific instrumentation characteristics, to ensure each piece of lab equipment functions within its required parameters for scientific accuracy. Here are some of the types:

- Pressure: Pressure calibration is essential for instruments that measure and control pressure within systems, such as pressure gauges, transducers, and manometers. This type of calibration ensures that equipment used in critical applications like oil and gas production, pharmaceuticals, and aerospace can maintain system safety and operational accuracy.

- Humidity and Temperature: This type of calibration is vital for instruments that monitor and control environmental conditions, such as thermometers, hygrometers, and HVAC systems. Humidity and temperature calibration are important in environments where precise atmospheric conditions are necessary, such as laboratories, clean rooms, and food processing areas to ensure product quality and compliance with safety standards.

- Mechanical: Mechanical calibration applies to devices that measure physical properties such as force, torque, mass, and dimensions. Instruments like scales, micrometers, and load cells are calibrated to ensure their output is accurate. This is particularly important in manufacturing and engineering, where precise mechanical measurements are crucial for product specifications and safety.

- Electrical: Electrical calibration is required for devices that measure electrical parameters like voltage, current, and resistance. Instruments such as multimeters, oscilloscopes, and power supplies need regular calibration to ensure they are providing correct readings. This is essential in electronic manufacturing, maintenance, and testing environments to prevent equipment failure, ensure safety, and support system integrity.

Steps to Choosing a Calibrator

- Third party calibrator, with independently assigned values, and which is not optimized to work with any specific instrument.

- Use a calibrator with the same matrix as a sample. (e.g. when calibrating blood tests ensure you choose a blood based calibrator)

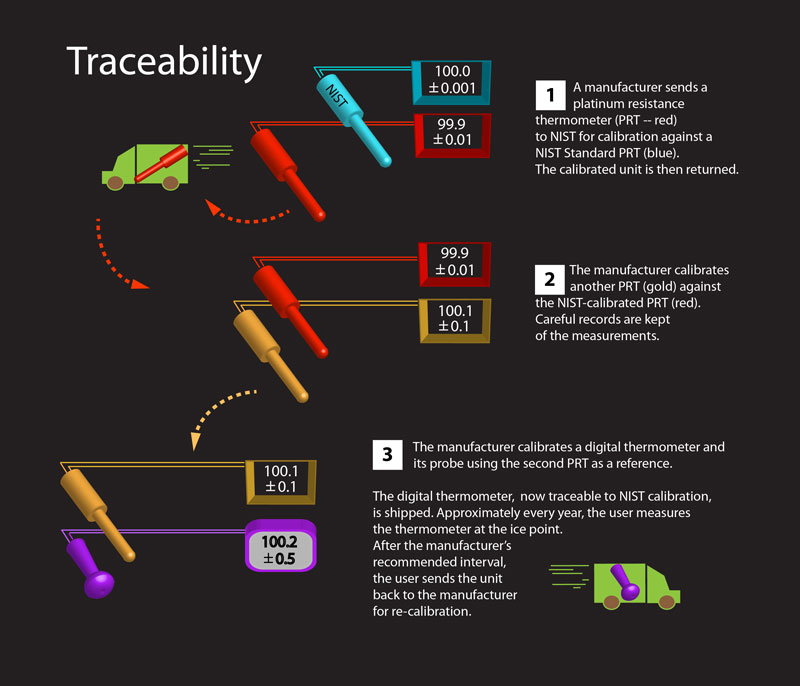

- Use a calibrator that is completely traceable to reference materials. This ensures comparable and accurate test results.

- Use a multi-analyte calibrator with a long shelf life. This will save your lab valuable time and money.

Steps to Proper Laboratory Calibration

- Follow the instrument’s or manufacturer’s instructions for calibration.

- Re-calibrate after major instrument maintenance. These can cause shifts in your test’s QC values.

- Re-calibrate every time a reagent batch is changed, unless you can demonstrate that changing reagent lot numbers does not adversely affect control values and patient results.

- Assess the required frequency of calibration when validating assays. Depending on the stability of the assay it may be necessary to recalibrate more/less frequently.

- Re-calibrate when your QC results are showing a systematic bias – calibration can eliminate trends or small analytical bias.

Calibration FAQ's

What is calibration?

Calibration in a scientific laboratory refers to the process of configuring an instrument to provide a result for a sample within an acceptable range. It ensures that instruments are producing accurate and reproducible results. Comparing the measurements of an instrument against a standard or reference with known accuracy will help ensure it produces accurate results.

The primary goals of calibration are:

- Accuracy: Calibration adjusts the precision of the instrument to conform to the standards, reducing the margin of error in the experiments.

- Reliability: Ensures that the instrument provides consistent results at different times and under varying conditions.

- Verification: Assists in verifying that the instrument performs as expected and meets the necessary specifications and regulatory standards.

- Data Quality: Enhances the overall quality of data collected, which is essential for research validity, regulatory compliance, and safety.

Calibration involves adjusting the calibration instrument, setting up calibration curves, or performing other mathematical adjustments to align the instrument's output with the standard's values.

Why calibration matters?

Regular calibration is important, especially in professional and research settings, where precision and accuracy are paramount for the validity of experimental results and product quality.

- Improves safety. Regular calibration ensures equipment operates within safe parameters, preventing accidents and hazardous situations. For example, calibrating temperature sensors in chemical reactions ensures processes don’t exceed safe limits, avoiding potential hazards like explosions or chemical burns.

- Saves money. By ensuring instruments are accurate, calibration helps avoid costly errors that could result from inaccurate measurements, such as the production of defective products or the need for additional testing. Early detection of discrepancies allows for corrections before significant resources are wasted.

- Gets you certified. Many industries require certifications that mandate regular calibration of equipment. Proper calibration records and adherence to standards can be necessary for compliance audits and to maintain certifications like ISO, which are important for business operations and credibility.

- Keeps instruments working longer. Regular calibration can extend the life of an instrument by ensuring it operates efficiently and within its intended specifications. Consistent checks can identify when an instrument is malfunctioning or wearing out, allowing for timely maintenance or replacement, thus protecting the investment in costly equipment.

Why is calibration important in a clinical or medical setting?

Calibration in clinical and medical laboratories is essential for ensuring the accuracy and reliability of test results. Accurate diagnostics are essential for correct patient diagnoses, effective treatment planning, and monitoring therapeutic outcomes, directly impacting patient safety. Additionally, regular calibration is mandatory to comply with stringent regulatory standards set by authorities like the FDA and CDC, which govern laboratory operations to maintain accreditation and legality.

It also maintains quality control by ensuring that labs produce consistent and reproducible results, for clinical research and patient care. Systematic calibration helps in detecting instrument anomalies early, potentially saving costs on repairs and preventing operational downtime. Maintaining calibrated equipment bolsters the laboratory's reputation by affirming its commitment to reliability and accuracy while fostering trust among patients and healthcare providers. Routine calibration is indispensable in clinical settings, safeguarding patient health, ensuring compliance, enhancing operational efficiency, and supporting the laboratory’s credibility in the medical community.

When Should You Calibrate Your Lab Equipment?

Calibrating your lab equipment regularly maintains accuracy, but knowing the best times to schedule calibration can optimize lab operations and ensure consistent data quality. Here are some instances when you should consider calibrating your laboratory equipment:

- Scheduled Calibration: Most equipment comes with a manufacturer's recommendation for calibration frequency. This could be annually, semi-annually, or quarterly, depending on the equipment's role in critical measurements and its susceptibility to drift.

- After Any Repair or Adjustment: If laboratory equipment undergoes any form of repair or modification, recalibration is necessary to ensure that it still operates correctly and provides accurate results.

- Following a Significant Event: Any event that could potentially impact the instrument's performance, such as a physical impact, electrical surge, or exposure to extreme environmental conditions, should prompt immediate calibration to confirm everything is still within specification.

- Before a Critical Measurement Series: If you're about to commence a significant experiment or measurement series, particularly in high-stakes research or manufacturing, recalibrating your equipment ensures that your data will be reliable and valid.

- When Measurements Seem Off: If the results from an instrument are consistently different from expected outcomes, or if the data suddenly deviates from usual patterns, it's a good indication that calibration may be needed to correct potential inaccuracies.

- Regulatory Compliance: For labs that must comply with specific regulatory standards, calibration might be required more frequently. Adhering to these standards often necessitates documented and traceable calibration processes.

By maintaining a regular calibration schedule and being attentive to these situations, you can significantly enhance the reliability, safety, and efficiency of your lab operations.