How To Handle a Temperature Excursion

What Is a Temperature Excursion?

When a vaccine or temperature-sensitive product is exposed to temperatures outside its recommended storage range, it’s called a temperature excursion. An excursion happens when the product is stored or in transit, which can cause an impact on its safety, efficacy, and quality. After a temperature excursion, companies should assess their procedures, storage, and transport units, and corrective measures should be implemented to ensure product integrity and safety.

How To Handle a Temperature Excursion:

To properly handle and manage a temperature excursion, follow these essential steps:

Identify and Verify the Excursion

Document the time, date, and duration of the temperature excursion and record the temperature range. To prevent use until you can verify their integrity, mark product labels as “Do Not Use.”

Assess the Severity and Impact By Evaluating the Condition of Affected Items

Evaluate the impact and severity of the temperature excursion. Examine the storage or transport unit’s power supply and temperature settings to ensure they are operating properly. Determine how long the temperature deviated out of range and how long the excursion lasted. The product’s stability data might provide insights about how it reacts to temperature changes. Because of their extreme sensitivity to temperature fluctuations, the integrity of some products may deteriorate. Assess the impact of the product being compromised on its intended use. Examine whether the excursion occurred during storage or in transit, as temperature excursions during shipment and storage often pose recurring risks.

Notify Key Stakeholders

Inform the manufacturer and key stakeholders about the temperature deviation. Their recommendations may include discarding, reconditioning, or continuing use, based on the data you provide, describing details of the excursion event that occurred. List the date, time, a list of affected products, and the recorded temperature range. Describe any corrective actions already taken, like isolating products and investigating the event’s cause. Explain the possible impact on product integrity and communicate corrective measures that have already been taken. Keep stakeholders informed with updates, especially important when handling temperature excursion pharmaceuticals.

Take Corrective Action

Corrective actions need to be taken after a temperature excursion to reduce risks and ensure products are safe. To avoid unintentional use, isolate the products right away and add “Do Not Use” labels to their containers. Transfer products to a backup storage unit until you can verify their safety. The product manufacturers may be able to determine if the products are unsafe or still usable, and they might advise you to discard damaged products or conduct tests to verify their efficacy and safety. These steps align with temperature excursion guidelines commonly used in regulated environments.

Determine the Root Cause

To ensure future product safety, integrity, and reliability, determine why the excursion happened, which might be a mechanical malfunction or human error. After you determine the cause, change standard operating procedures, and tell employees about the changes in monitoring systems to prevent temperature excursions from happening again.

What Are Common Causes of Temperature Excursions?

A temperature excursion is caused by factors that might occur during manufacturing, storage, or transportation. Equipment malfunctions are a frequent cause. For example, refrigeration units or HVAC systems that maintain controlled environments can fail. Mistakes in setting temperature controls, leaving doors open, or not managing temperature controls properly are human errors that can cause excursions. Environmental conditions like unexpected transit delays or extreme weather can lead to fluctuations in the temperature. Inadequate packaging or insulation may cause ambient temperature changes. Power outages sometimes interrupt the operation of temperature-controlled systems. Incorrectly loading or stacking goods can prevent airflow in transport or storage units, causing temperature variations or potential excursions.

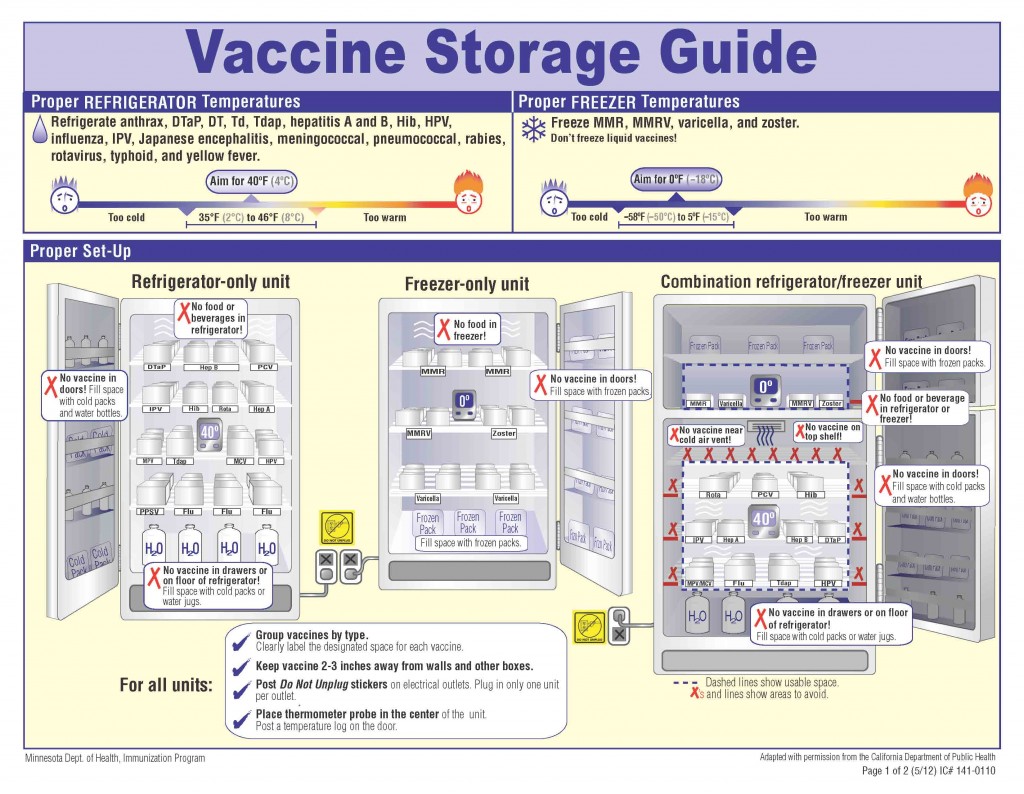

What Products Are Most Affected by Temperature Excursions?

Products most impacted by temperature excursions are the ones made with biological or chemical structures that affect their efficacy, stability, or safety. Even minor deviations in temperature can cause blood products, insulin, biologics, and vaccines to become vulnerable to temperature excursions, unsafe, and ineffective. Improper temperature control can cause perishable food products like dairy, meat, seafood, produce, and frozen goods to spoil, change their texture and flavor, or cause foodborne illnesses to develop. When stored at improper temperature ranges, chemicals like resins, adhesives, and organic peroxides can become hazardous. Under hot or cold conditions, beauty products like lotion and sunscreen can separate or experience a change in consistency. Even wine can prematurely age or suffer damage when exposed to excursion temperature events.

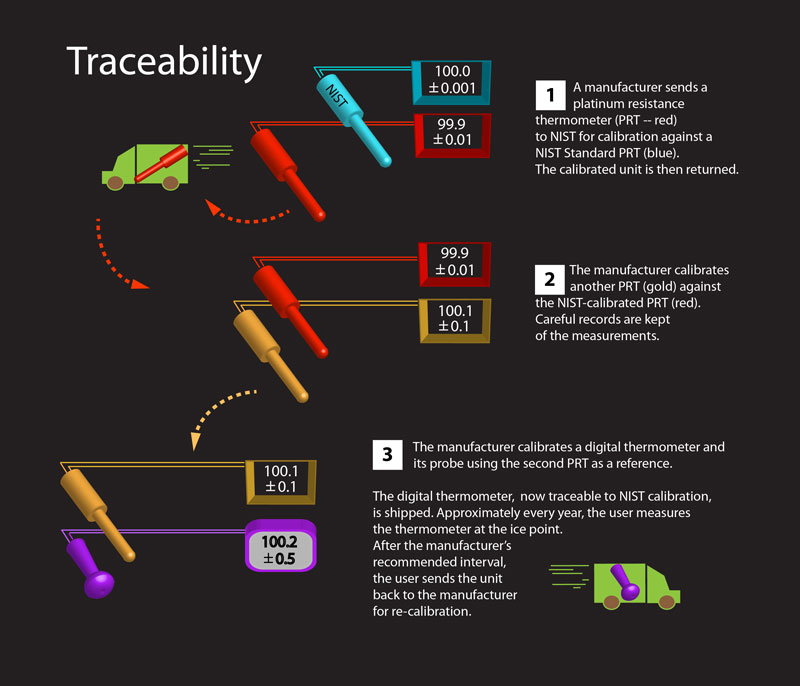

How To Measure Temperature Excursions

Measuring temperature excursions includes using calibrated temperature monitoring digital data logger devices to track and record temperature data continuously. These devices are positioned in the storage or transport environment with temperature-sensitive products. At predetermined intervals, they record the temperature with a time-stamped log of temperature conditions. The data helps identify the excursion and is analyzed and compared against the pre-defined, acceptable temperature range for each product. A temperature excursion is a reading outside of the pre-defined range, combined with its duration. E-Control Systems sensors provide real-time alerts when excursions happen, allowing immediate corrective action to be taken. Information from the recorded data helps reduce future impact on product safety and quality, and follows regulatory guidelines.

Can Wireless Temperature Monitoring Prevent Temperature Excursions From Happening?

By providing real-time tracking and alerts, wireless temperature monitoring prevents temperature excursions. E-Control Systems makes wireless temperature monitoring sensors to continuously monitor temperatures and transmit data to a central platform. The system sends real-time data to email or SMS notifications if the temperature deviates from the preset range. It provides instant information about the storage conditions. This complies with safety regulations and reduces the possibility of damage while minimizing losses. Wireless temperature monitoring systems can be customized for different applications in many industries. They’re an easy and effective way to ensure temperature-sensitive environments function properly and safely.